Capabilities

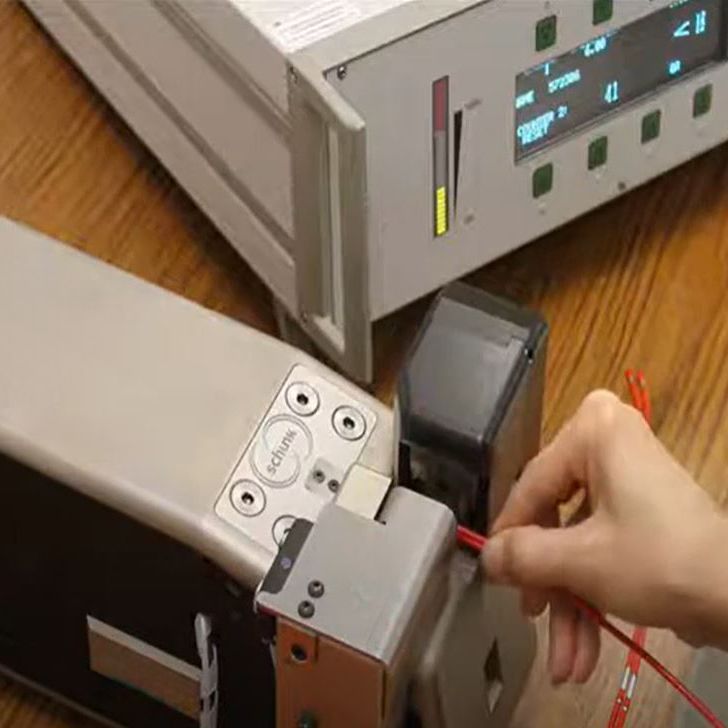

- Semi-automatic terminal application

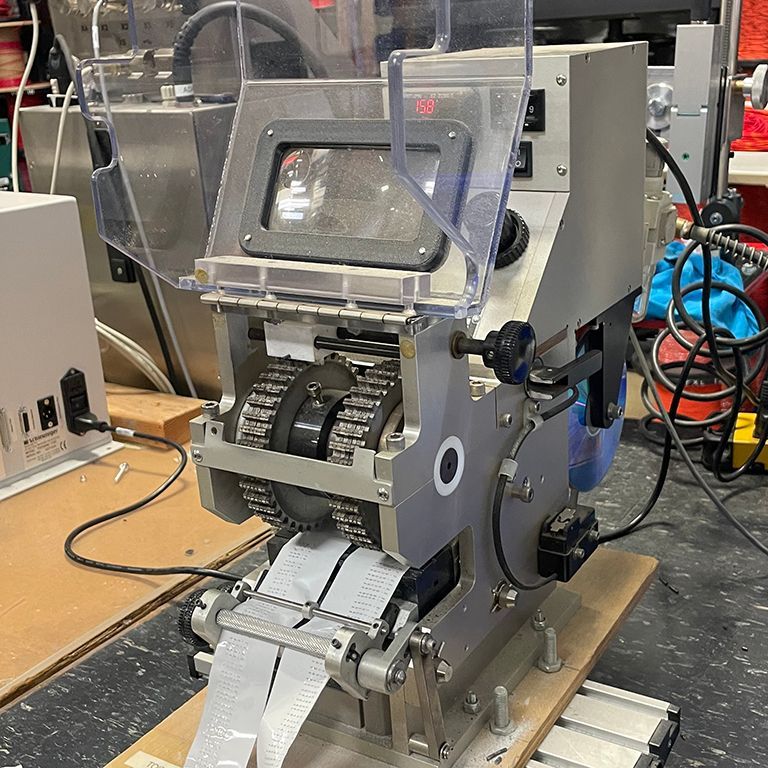

- Auto wire processing

- Braiding

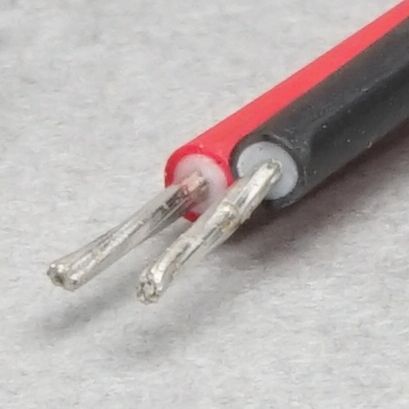

- Battery cables

- Wire tinning- Lead and lead free

- Control box assembly and wiring

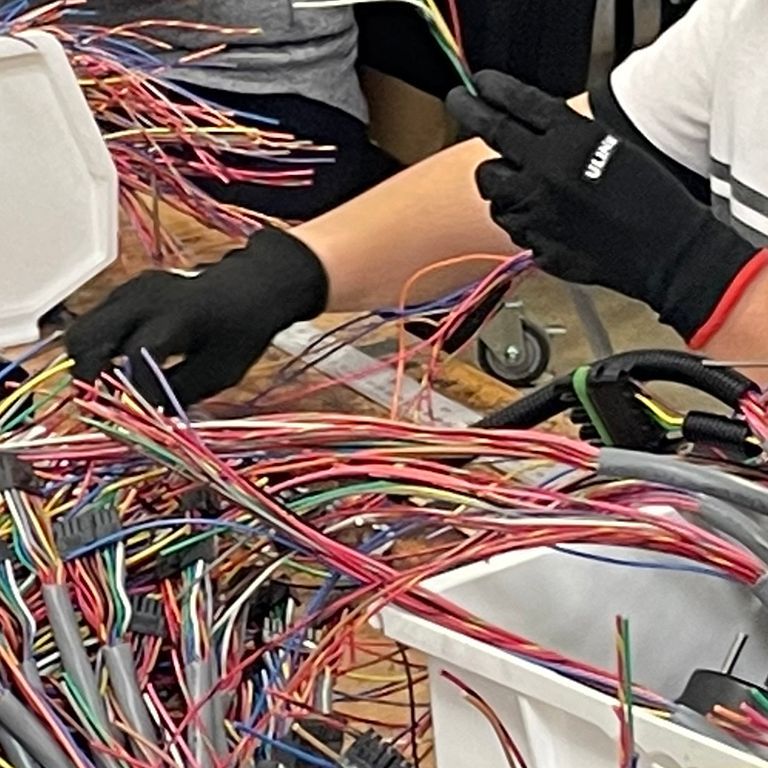

- Long harnesses 25’ and up

- Power cords and molded assemblies

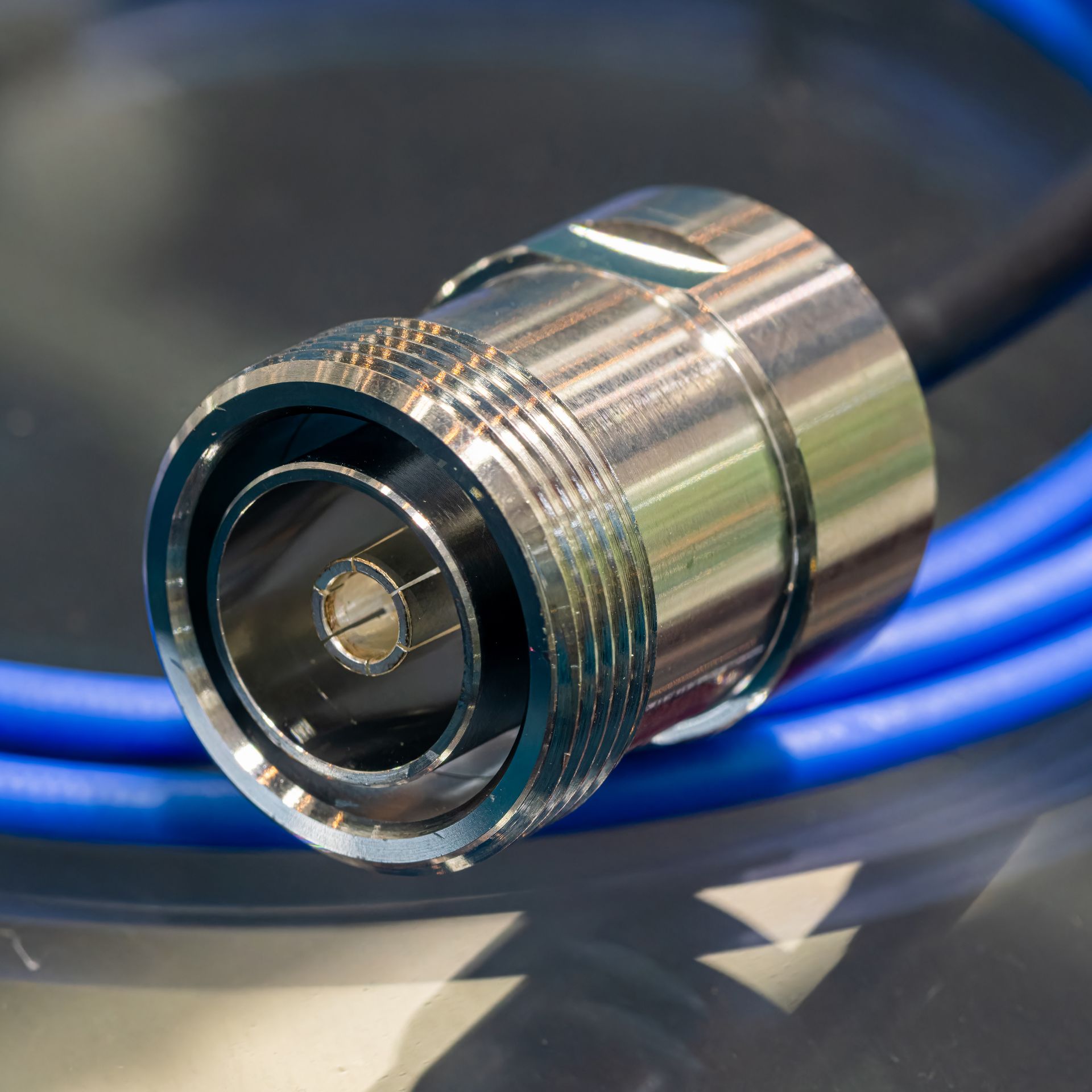

- Coax cable assembly

- IDC connector application

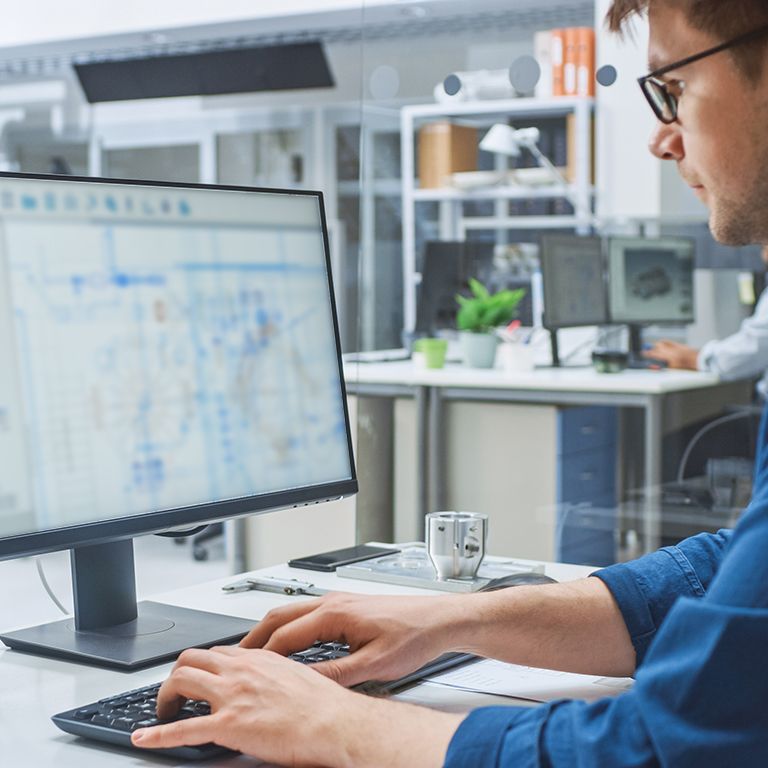

- Harness board design and board assembly

- Engineering support

- Concept development- We can design or re-design harnesses to minimize cost and maintain high quality

- Component sourcing

- Kitting of harnesses- We can provide plug and play kits complete with harness, power cables and controls for ease of customer line assembly

- Ink jetting and labeling

- Sonic welding

- End of line testing - Continuity testing on 100% of point-to-point harnesses - capable of detecting diode reversal as well as incorrect diode or incorrect resistor values

- 3-5 Day quote process

- Short and flexible lead times

- Harness rework and revisions

- Warranty work

- Domestic support and logistics